Colours & Coatings

Colours add personality and character to your building. We present you the main colour palette of Technopanel

* Special colours on request

- The described colours should be interpreted as approximate

- No guarantee for identic color shades on partial or additional deliveries due to the possibility of using different coils. In order to avoid nuance differences, complete information should be provided when ordering.

- Larger shade differences are possible with PVDF coatings

- Additional panels in reserve should be calculated when ordering specific colours

- Large temperature differences may occur between the internal and the sun exposed external sheet of the sandwich panels. As a result of the high coefficient of thermal expansion of the sheet, bending and tension stresses can be obtained in the cross-section of the panels. Special attention should be paid in this direction for colours of II and III colour group, and particularly for sandwich panels with PIR insulation core.

- Colour groups are defined according to EN 14509

Metal sheet Coatings Comparison

| Resistance / Type of coating | Polyester PE | PVDF | PVC | Special coating *on request |

|---|---|---|---|---|

| Bending resistance | 3 | 4,5 | 5 | 3,5 |

| Surface hardness | 4 | 3 | 2 | 5 |

| Chemical resistance | 3 | 4,5 | 5 | 5 |

| Humidity resistance | 3 | 4,5 | 4,5 | 5 |

| Corrosion resistance | 3 | 4,5 | 4,5 | 5 |

| Colour and gloss stability | 3 | 5 | 2 | 5 |

| Environmental conditions / Type of coating | Polyester PE | PVDF | PVC | Special coating *on request |

|---|---|---|---|---|

Building Design Guidelines

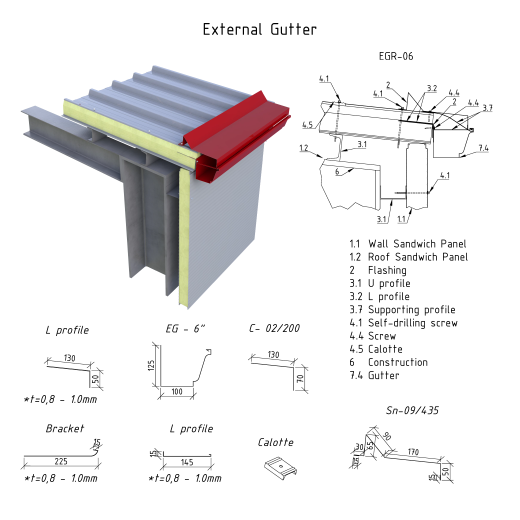

As already mentioned, the risk of corrosion strongly depends on the time during which the panels remain wet. Therefore, one of the most important design rules is to provide the building with appropriate drainage system. Avoid design solutions, which may facilitate water accumulation and retention. Here are some suggestions on how to design panel roofs and walls:

Roofs

- Low pitch roofs are most prone to corrosion caused by adverse environmental conditions, such as high levels of UV radiation, acid rains and wind-blown chemical contaminants. Efforts should be made to avoid retention of water at such points as the panel overlapping lines, vents, exhausts, air conditioning equipment, etc. There shall be envisaged passage routes for maintenance purposes to prevent damages to the panel coating.

- The effective catchment of rainwater at the roof corners depends on the slope of the roof. Roofs with greater slope have better corrosion resistance at their drainage points.

- Various metals, such as steel, aluminium, copper, lead, etc., shall not be in direct contact with one another to prevent the possible electrochemical corrosion. In addition, in order to avoid the effects from other sources of electrochemical corrosion, the path of the water shall be selected in such a way to avoid its running from one type of material to another.

- To reduce the damages caused by the UV radiation, use roof panels painted in lighter colours.

- The panels’ useful life is shorter in the areas of the roof where snow is accumulated and remains unmelt for longer periods of time. If the building design provides for heating of the area immediately below the roof panels, the snow on the panel can keep on melting throughout the whole winter. This continuous melting however will result in prolonged contact of the panel’s coated surface with water. As explained above, water can penetrate through the coating and cause severe corrosion thus shortening the panel’s life. If the roof is insulated so that the roof panel remains cold, the snow will not melt continuously which will prevent the formation of voids and zinc corrosion. It should also be taken into account the fact that the thicker the polyester coating of the sheet, the more resistant to moisture it is.

Walls

- Vertical façade walls are less exposed to weathering than the other surfaces of the building and get less damaged, except for the shady areas.

- The panels installed in shady areas, for example, in wall recesses, under roof overhangs, etc., are less exposed to sunlight and rain. However, corrosion processes in such areas run faster, because the dirt deposited on the walls is not washed away by the rains. In addition, the moisture caused by the condensation cannot dry out due to lack of direct sunlight. Special attention shall be paid to the shady areas of the buildings located in industrial zones, coastal regions or near the heavily trafficked roads.

- The horizontal parts of the wall cladding shall have sufficient slope to prevent the accumulation of dirt and water. This is especially important for the plinth cladding, as the insufficient slope can cause corrosion of both the cladding and the panels.

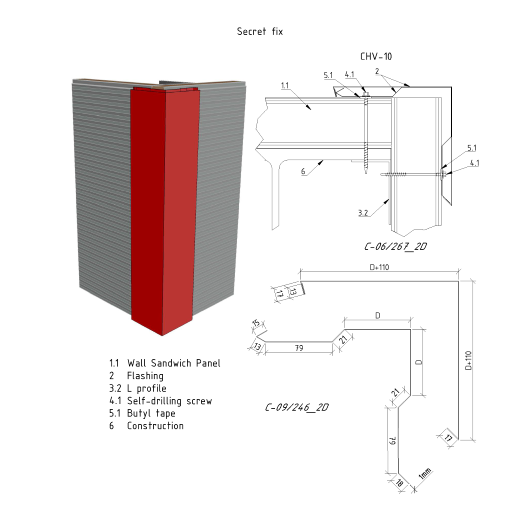

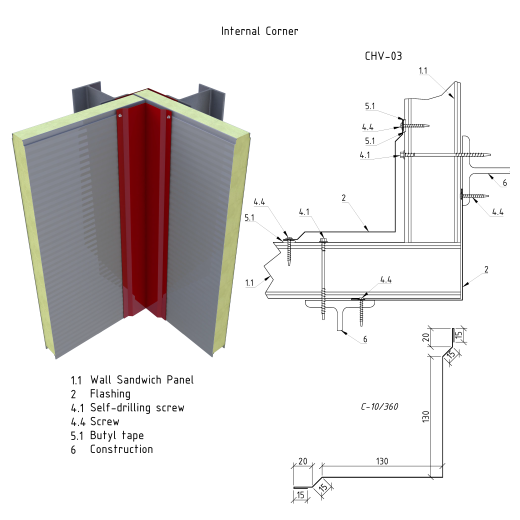

- Various metals, such as steel, aluminium, copper, lead, etc., shall not be in direct contact with one another to prevent the possible electrochemical corrosion.

- As with roof panels, corrosion can be a problem for wall panels in areas with heavy snowfall. Snow shall be removed from the areas adjacent to the building. Alternatively, good insulation practices shall be applied to avoid the prolonged melting of the snow accumulated on the surface of the walls panels.

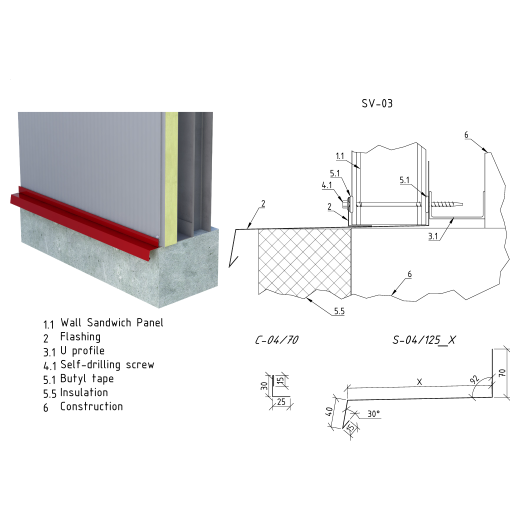

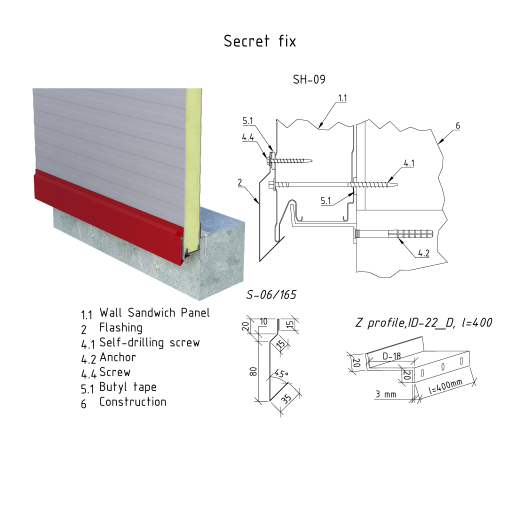

- Avoid the accumulation of moisture in the panels’ insulation and core by using good insulation practices. If the insulation gets wet, it dries very slowly or does not dry at all. Again, this causes the surface of the panel to be covered with moisture for a prolonged period of time - a condition that leads to accelerated damage. The most common situation is when the insulation at the bottom of the façade panels gets wet due to water retained at the foundations. This problem can be minimized by installing the panel in front of the foundation slab rather than directly on it.

- The galvanized and coated steel sheets shall not come into contact with wet concrete. The high alkalinity of the concrete attacks the aluminium and causes coating to flake. If fasteners are to be used for installation purposes, care shall be taken their useful life to be the same as that of the panel. Today, one can find on the market screws/fasteners with organic coating, which provides good corrosion protection.

- The substructure for the sandwich panels (panel supports) shall not be less than 60 mm wide.

- When installing panels horizontally, the width of the end panel support shall be at least 140 mm, and the gap between the two end panels shall be at least 40 mm.

- When installing panels horizontally by applying a multi-span system, the panels shall be fastened to the middle support(s) with 2 screws, while the respective distances between the supports shall be determined by static calculations taking into account the load-bearing capacity of the panels.

It is recommended to use a self-adhesive sealant for the end panel supports. It is also recommended to use a self-adhesive sealant for the vertical part of the plinth cladding.

Handling, storage and assembly of sandwich panels

Packaging, Transport and Unloading

- maximal weight per pack – 2150 kg

- minimal pack length – 2500 mm

- maximal pack length – 16000 mm

- maximal pack width – 1200 mm

- maximal pack heigh – 1200 mm

The vehicle to carry the panels should be equipped with cargo straps to ensure the cargo on the vehicle bed. Protective angular elements should be installed at the cargo straps to protect the edges of the panels. In case of flashing packages are being transported with the panel packages, they should be fastened separately.

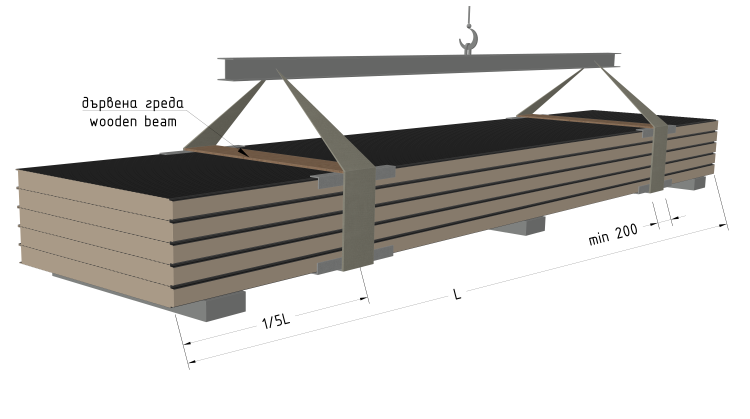

If the stack is long particular attention should be paid to the bending and deflection. These problems are eliminated with the use of a crane beams and sleepers.

Stacks up to 6m can be raised and forklifts. Packets with length of 6m to 13,5 m should be lifted by crane or with forklift for long panels. To ensure protection of the edges of the panel in loading and unloading activities carried out by crane with lifting belts, stacks need to be reinforced at the bottom and at the top with protective angular elements that accompany the panels in each expedition.

Storage considerations

Do not keep the package of panels at a job site or warehouse more than 3 months. Put the packages with 5% slope, in order to prevent the water collection between the panels! Do not store more than three packages one on top of another and place spacers or board between them!

Instalation guidelines

During the installation of the panels there are often trimming operations on site needed. In those cases the following must be taken into account:

- During the cutting procedure, the panels must be laid horizontally and must be well supported on a workbench or on level supports with a soft surface (e.g. a wooden palette with polystyrene pieces, etc.

- Openings cut in roof and wall components, before the panel is assembled, weaken its cross-sectional structure, therefore adequate stiffening should be provided in those places.

- The cutting of roof covering materials is also possible when they have already been fixed in their final position on the metal frame of the building. In this case, make sure that they are firmly in place and not liable to wobble as they are being cut.

- If the panel is thick and it is difficult to cut the outer steel sheet and the inner aluminum/paper sheet of the panel at the same time, then the cutting line must be marked on both metal sheets so that the cutting can be carried out in two steps.

- During the installation often are formed clippings and/ or filings as a result of cutting the panel or using self-drilling screws. If they are not removed promptly from the panel surface they will corrode and cause rust staining, which is undesirable especially if the paint color is bright.

- The cutting tools must make the cutting clean and easy and must not damage the panel surface. For this reason, it is suggested that the cutting be done using a disk saw rather than a cutting wheel, with suitable guides for the best cutting line. Moreover, the disk saws must be of high quality to avoid damage to the cutting surface.

Use manufacturer recommended self-drilling fasteners for fixing the sandwich panels. The fastener type will depend upon the load carrying and the thickness of the panel being assembled.

In order to achieve adequate fastening of the panel to the structure it is essential to maintain perpendicular fastener position while fixing.

Use stainless steel fasteners for fixing panels to structures where the following conditions are preset:- The atmosphere inside is characterized by a permanent moisture content of above 70%.

- Chemically aggressive atmosphere is present inside.

- The equipment stored requires particular protection.

For panels with through fixing or / and when cutting panels on the site is needed, the recommended minimum distance of the screw from the end of the panel is 3-4 cm.

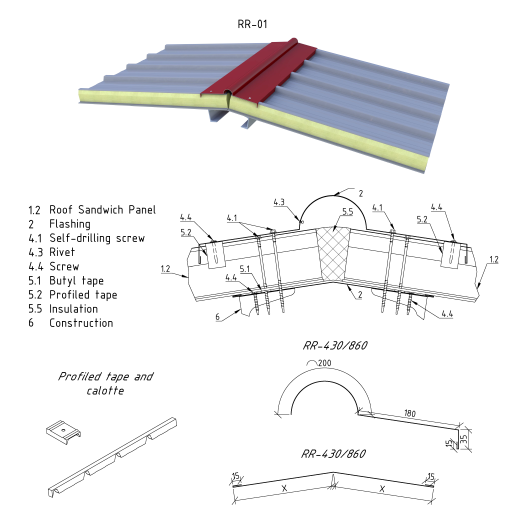

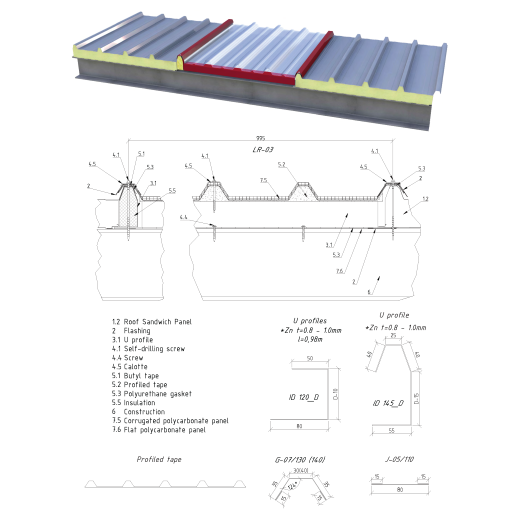

Roofing, Overlapping and Natural roof lighting with Polycarbonates

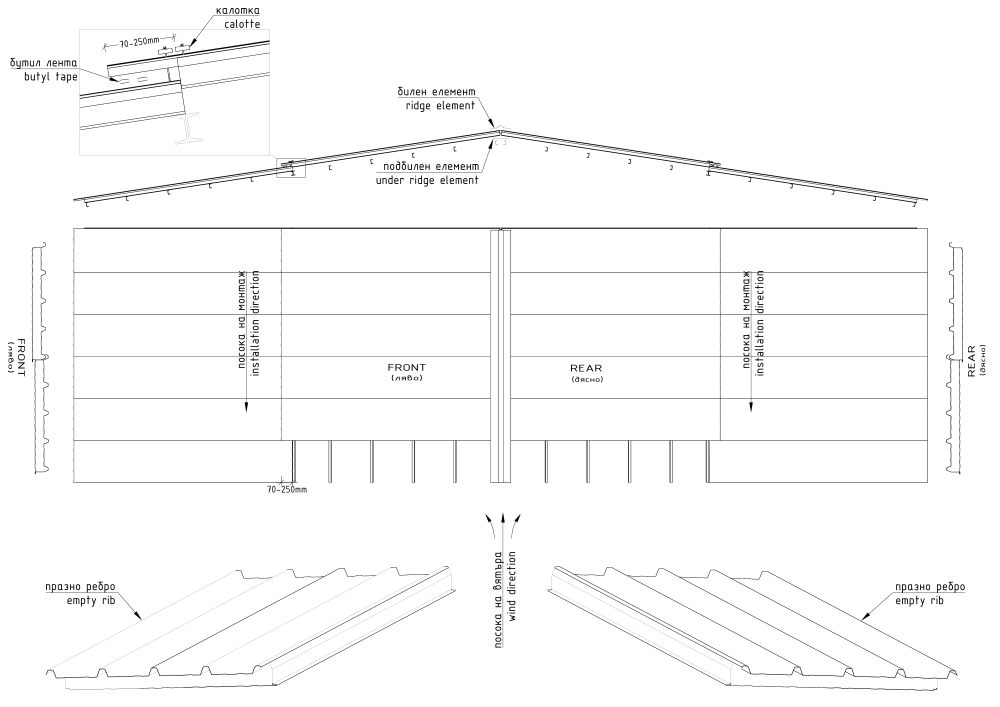

To prevent water ponding you should comply with the requirements for a minimum gradient of the slope as follows:

- min 7% (40) - for roofs of continuous panels without transverse joining and skylights.

- min 10% (5.70) - for roofs of joint panels or with skylights.

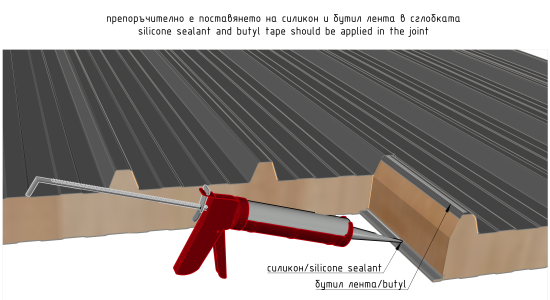

When overlapping is required or there is a low slope roof and / or for better water withdrawal at the roof, Technopanel offers a factory cut of the panels of 70 to 250 mm.

Policarbonates are an excellent material for the realization of natural roof lighting. Corrugated polycarbonates are mounted starting from the ridge. To ensure water impermeability of the connection with the gutter, it's reccomendet for the policarbonate at the bottom of the roof to overlap the sandwich panel. The overlapping of a polycarbonate panel on a sandwich panel is handled the same way as the overlap between two sandwich panels, with two rows of insulation gasket.

The polycarbonates are pre-drilled and the opening must be slightly wider than the screw to allow free movement due to thermal expansion. The use of callots is mandatory.

EN

EN БГ

БГ DE

DE РУ

РУ RO

RO СР

СР